The Electronic Devices Business consists of two segments: Devices, Assembly.

The iTak Group works proactively as a single business unit through strong cooperation between each site to cover all of the main countries in Asia. The ability to offer global manufacturing support for customers’ development, production, and purchasing from an office near to their site is one of the characteristics of the iTak Group.

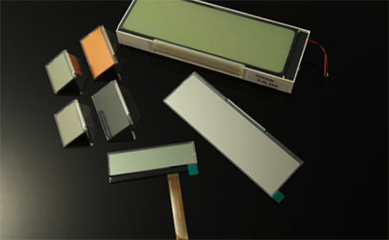

We provide LCD displays for a broad range of applications, from consumer products to automotive and industrial equipment, as well as audio products (microphones, speakers, receivers, etc.), and power electronics-related parts such as semiconductors, capacitors, and relays. We operate a business that leverages our customer support capabilities by capturing their needs, undertaking procurement primarily from Asian manufacturers, and systematically implementing delivery control, inventory management, and quality management for parts.

|

Visual component products |

Mono LCD (TN, STN, FSTN, VA, etc.) |

|

COG module / Backlight module |

|

|

TFT display/ OLED display/ Touch panel etc. |

|

|

Sound component products |

ECM microphone / MEMS microphone |

|

MIC board module / Module with cable |

|

|

Speakers/ Receivers, etc. |

|

|

Semiconductor transistors & diodes |

Diodes in general/ TVS/ FET / Transistors/ Analog ICs |

|

Electrolytic capacitors/ Film capacitors |

|

|

Power relays/ Latching relays/ Communication relays |

|

|

Transformers/ Choke coils/ LEDs |

|

|

Infrared light emitting diodes/ Photodetectors/ Photo interrupters/ UV LEDs |

|

|

Terminal blocks/ Microswitches/ Connectors, etc. |

Microphones

Liquid crystal displays

Capacitors

Utilizing our own plant in Thailand, our EMS business provides total support for PCB mounting in white goods and a wide range of other products, from design stages to mass production. With its background as an electronic components trading company and its capabilities as a manufacturer, the iTak Group has created a structure that enables it to supply competitive products as a “trading company + manufacturer.” Its assembly services contribute to energy savings and the shift to inverter usage by white goods and other products through production at its Thai plant.

The Chonburi factory was established in November 2017. We are certified as BOI company and provide mounting boards to customers who manufacture home appliances to be exported to Japanese companies and other countries around the world.

We also support special processing such as urethane potting, and we also produce circuit boards that require waterproof processing such as washing machine substrates.We also have a mounting machine for SMT and radial axial parts, and integrated production is possible together with the automatic soldering line.

Taking advantage of our strong relationship with parts manufacturers and the network of the entire group, we also propose and support Value Engineering projects. We also produce transformers and choke coils, and by producing key parts for power supply boards in-house, we can shorten delivery times and reduce costs.

In addition to our own mounting factory in Chonburi, Thailand, we will provide manufacturing in Asia in cooperation with our partner companies. We are also able to mount on FR-1, FR-4, CEM-3 boards, FPCs, different-shaped boards, individual boards, and metal plates. We have a lot of experience in mounting sensor components on FPCs, and we offer a wide range of services for modification and analysis of manually mounted components.

We produce near the customer’s overseas factory with local professional staff overseeing QC and provide support from trial production, small lot production to mass production.

iTak International (Thailand) Limited - Chon Buri Factory

Related Contents